Transform your ideas into precision parts with our fast and reliable CNC solutions.

Achieve success with our advanced technology and expertise.

Businesses involved in large-scale manufacturing that require precision parts, such as those in automotive, aerospace, and electronics sectors. We offer high-volume production of complex parts with stringent quality control to meet their exacting standards.

Companies that design products and need prototypes or small batches of precision parts, including product design and R&D departments. We provide custom prototypes, rapid turnaround, and expert design support to help bring their ideas to life.

Businesses that supply parts and components to the automotive industry, including car manufacturers and parts suppliers. We deliver high-volume, cost-efficient production with consistent quality to keep their operations running smoothly.

Companies that create custom parts and products based on specific client needs, such as those in specialty manufacturing and custom engineering. We offer the flexibility and bespoke solutions needed for small-to-medium batch production, tailored to their unique requirements.

Institutions focusing on developing new technologies and products, such as academic research labs and corporate R&D departments. We provide precise prototyping, innovative materials, and high-quality precision to support their cutting-edge work.

Companies that require parts for large machinery and construction equipment, such as those in the construction and mining sectors. We offer durable, precision-made components designed for heavy-duty applications and large-scale manufacturing.

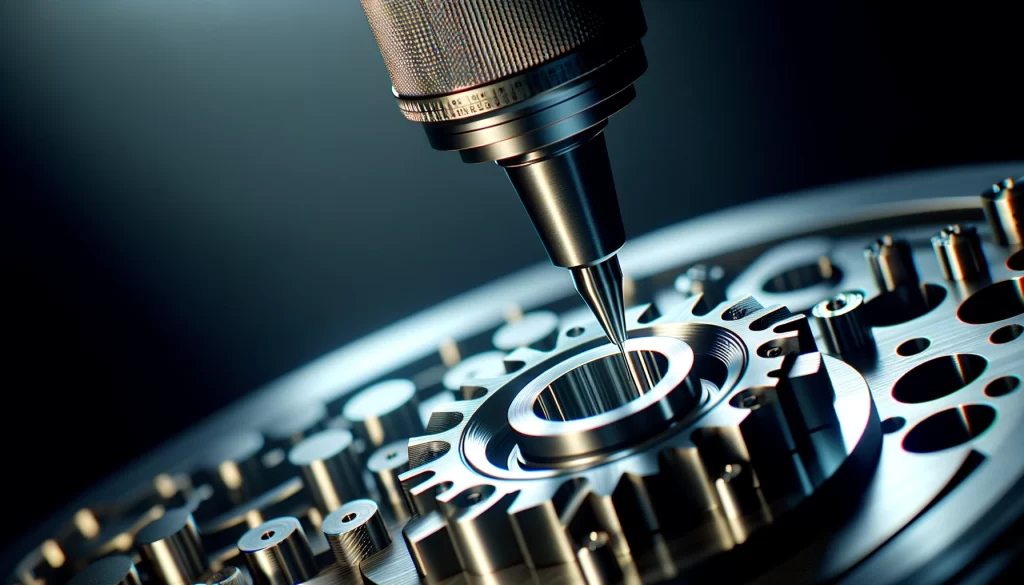

Our advanced CNC machines, equipped with the latest 3-axis technology and high-speed machining (HSM), enable us to produce complex parts with remarkable accuracy. Utilizing CAD/CAM software, we improve the quality, speed, and efficiency of production—minimizing errors and accelerating delivery times, so our clients receive superior parts, faster and more reliably.

We specialize in delivering CNC solutions precisely customized for each client. Whether you require a prototype or large-scale production, our collaborative approach ensures that every part meets your exact specifications, resulting in exceptional quality and satisfaction.

Our streamlined processes enable us to deliver some of the fastest turnaround times in the industry, all while maintaining the highest quality standards. This commitment makes us the ideal choice for businesses requiring quick and reliable delivery without compromising on excellence.

With extensive experience in the train transportation, automotive, construction, and heavy machinery industries, we understand the critical importance of precision and compliance with strict standards. Our deep knowledge of these sectors’ unique requirements ensures top-tier results for every project, tailored to meet industry-specific demands.

We go beyond machining by offering design consultation, material selection guidance, and finishing services, providing end-to-end support for your projects. With everything managed under one roof, you can streamline your process and ensure seamless project execution from start to finish.

Our rigorous quality control process guarantees that every part meets the highest standards of accuracy and durability. Using the Wireless Intuitive Probing System (WIPS) on the machine, we conduct in-process inspections to deliver flawless results our clients can trust.

Our vision is to be the leader in innovative CNC machining services, renowned for our unwavering commitment to quality, precision, and exceptional customer satisfaction.

Our mission is to deliver precision-engineered CNC machined parts that meet the highest industry standards, enabling our clients to achieve their production goals with maximum efficiency and accuracy.

Benefit: The chip auger is an automated system that efficiently removes chips from the machining area, keeping the workspace clean and preventing chip build-up during operations. It continuously transports chips to the disposal area without manual intervention.

Advantage: By maintaining a cleaner work environment, the chip auger reduces downtime for manual clean-up and prevents damage or interference caused by chip accumulation. This leads to smoother operations, improved productivity, and longer tool and machine life.

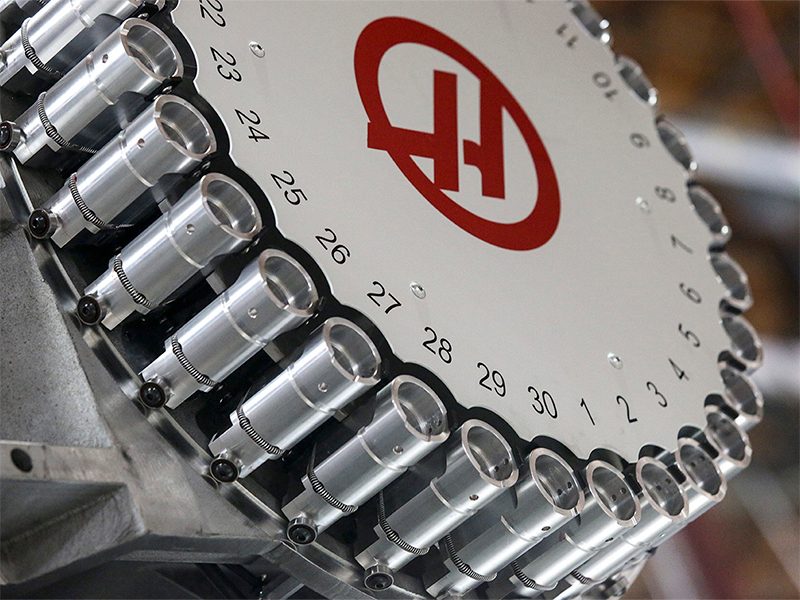

Benefit: The 30+1 side-mount tool changer allows for fast, efficient tool changes, minimizing downtime between operations. The machine can quickly swap tools during multi-step jobs, ensuring continuous machining without unnecessary delays.

Advantage: Faster tool changes mean higher productivity, especially when dealing with complex jobs that require multiple tools. This boosts throughput while maintaining flexibility.

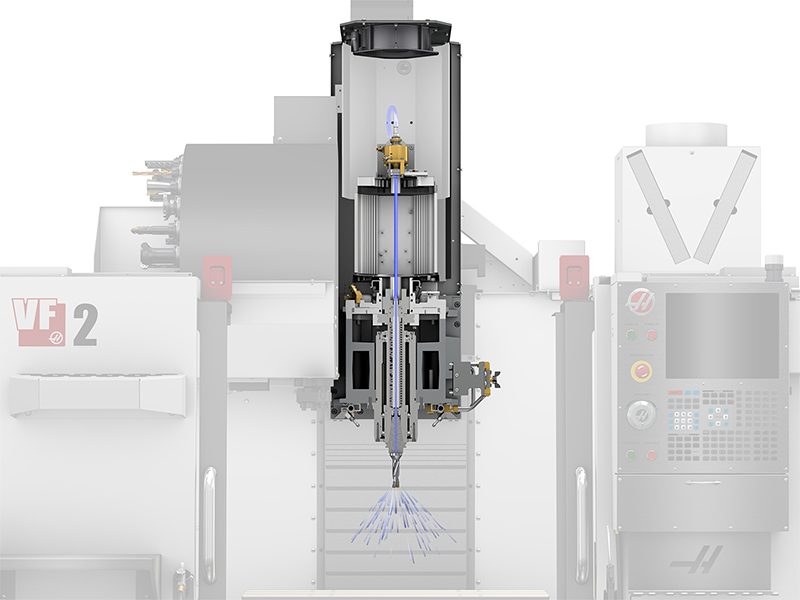

Benefit: The Through-Spindle Coolant (TSC) system delivers high-pressure coolant directly through the cutting tool to the cutting edge. This enhances cooling and lubrication exactly where it’s needed, even in deep holes or challenging cuts.

Advantage: TSC improves chip evacuation, reduces tool wear, and allows for faster feed rates, leading to increased cutting speeds, longer tool life, and better surface finishes. This results in greater efficiency and fewer interruptions during complex or deep-hole machining operations.

Benefit: The Wireless Intuitive Probing System simplifies setup and part inspection by automatically measuring tool offsets and part features. This reduces human error and speeds up the setup process.

Advantage: WIPS increases productivity by reducing manual measurement and improving consistency in accuracy, allowing machinists to focus on other tasks while the machine handles probing.

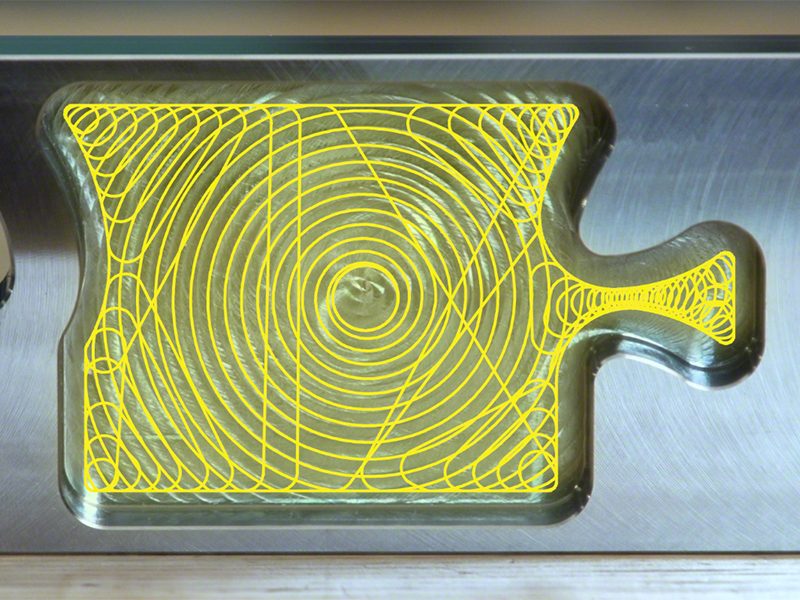

Benefit: The HSM option optimizes the machine’s control system for smooth, precise tool paths at higher feed rates. This allows the VF-4SS to handle complex geometries and intricate details without compromising accuracy.

Advantage: Faster processing of intricate designs means shorter cycle times and the ability to tackle more sophisticated parts with precision, reducing lead times

Complete this form and we will get back to you promptly.